Xerxes Scientific is a new company that was created to offer semi-custom telescope mounts and control systems for astronomical imaging. Their initial products are D11 and D21 direct drive modules which are part of their modular telescope mount system, which can either be incorporated into custom telescope mounts or be provided with mounting hardware in kit form for ready assembly and installation at the customer’s site.

In addition to direct drive modules, also in development are modular friction drive components which can be used with telescopes ranging from small consumer telescopes to observatory class instruments weighing up to 1,000 lbs. According to the firm, “Our design philosophy emphasizes the use of the latest generation of industry standard electronics and control protocols, which protect your investment by future-proofing the electronics, which are the least reliable part of a telescope control system.”

The Xerxes Scientific D11 Modular Direct Drive System comprises a custom-built high torque direct drive servomotor, precision 26-bit absolute encoder, and CANopen compatible electronic controller. Two D11 modules can be combined to create a custom equatorial, alt-alt, or alt-azimuth telescope mount. These direct drive systems work well for telescope pointing and control as they eliminate backlash as well worm gear adjustment and alignment. Direct drive systems also automatically compensate for disturbances to the telescope such as wind gusts.

Xerxes Scientific D11 Modular Direct Drive System Design characteristics include:

– 210mm OD (150mm ID) high rigidity crossed roller bearing eliminates preload adjustments and is fully rigid in all axes

– 11 N-m (D11) to 21 N-m (D21) continuous torque output easily accommodates common imbalance issues

– 34 N-m (D11) to 64 N-m (D21) peak torque

– 200mm Renishaw precision code ring provides higher precision than competitors with 150mm code rings

– 26-bit industry-standard absolute BiSS encoder

– CANopen interface compatible with all Modular Direct Drive Components and many other industrial control products

– NexStar emulation

– ASCOM over ethernet interface for common astronomical control software (using host PC)

– Overall dimensions of motor: appx. 250mm x 145mm

– Unit weight: 45 lbs

– Servo Drive (per axis): 115VAC power, 6A continuous, 18A peak, plus 24VDC 1A auxiliary supply in NEC electrical enclosure

– Servo drive safety approvals: IEC 61010-1:2001, UL 61010-1

What is CANopen?

According to the company, CAN (Controller Area Network) was originally developed by Bosch for use in automobiles but is now the de facto standard for industrial control systems. CAN data buses provide two-way communication between nodes, using an eight-byte message payload, and provides speeds up to 1Mbit/sec.

CANopen is an open standard protocol for industrial control systems using the underlying CAN physical and logical layers. CANopen servo drives are widely available and constantly being improved which provides future-proofing to the system designer and customer. Multiple drive axes, sensors, and control end points (such as a hand controller, ST-4 guide port, tilt and temperature sensors) can be attached onto the common bus and the Xerxes Modular Drive system provides a simple cable interface for all equipment, using only four wires.

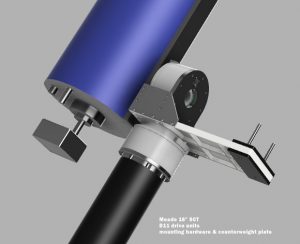

CANopen control technology for telescopes was developed and tested on Xerxes Scientific’s traditional DC servo drive system currently installed at their observatory in Eastern Washington, which carries a Meade 16″ f/10 SCT on a custom offset axis equatorial mount.

And to make it easier for you to get the most extensive telescope and amateur astronomy related news, articles and reviews that are only available in the magazine pages of Astronomy Technology Today, we are offering a 1 year subscription for only $6! Or, for an even better deal, we are offering 2 years for only $9. Click here to get these deals which only will be available for a very limited time. You can also check out a free sample issue here.